July is the height of summer grilling season, and throughout the month USDA is highlighting changes made to the U.S. food safety system over the course of this Administration. For an interactive look at USDA’s work to ensure your food is safe, visit the USDA Results project on Medium.com and read Chapter Seven: Safer Food and Greater Consumer Confidence.

Keeping the food on America’s tables safe to eat is a major priority at USDA, where we are constantly working to find innovative ways to stay a step ahead of bacteria and other dangerous contaminants that can cause illness. Thanks in part to a grant from USDA’s National Institute of Food and Agriculture (NIFA), a research team led by Dr. Bryan Chin, director of the Auburn University Detection and Food Safety Center, has developed a cheap, portable and easy-to-use new screening tool to test fresh fruits and vegetables for the presence of bacteria that can cause foodborne illnesses.

Currently available screening methods for produce can be costly in terms of time, equipment, and expertise. The multidisciplinary research team of engineers, microbiologists, and genomicists based at Auburn University and the University of Georgia wanted to create a new method that could be used more broadly.

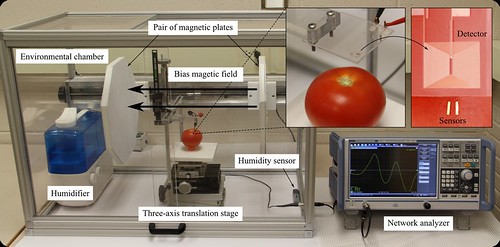

The team has developed biosensors that are placed directly upon the fresh fruits or vegetables being analyzed. The eyelash-size biosensors are coated with antibodies and phages (viruses that target specific bacteria) and vibrate when placed within an oscillating magnetic field. If targeted bacteria are present, they bind to the antibodies and phages and change the vibration frequency of the biosensor. These frequency changes help inspectors determine the type and amount of bacteria on a given fruit or vegetable.

“The technology gives us a revolutionary new capability to directly detect food pathogens,” Chin said. It is fast and has both high specificity and sensitivity. In less than 12 minutes, the sensors can detect as few as five hundred Salmonella cells amid a sea of a million bacterial cells. The measurement system costs $750, with each of the disposable biosensors costing less than 1/1000 of a cent.

The biosensors are still in the research and development stages. Moving forward, Chin has his sights set on developing a technology that is even faster and is capable of screening an entire bulk shipment of product, removing sub-sampling entirely.

USDA consistently conducts and funds food safety research to generate real-world results for both government and the private sector. In 2014 alone, USDA’s NIFA provided more than $112 million for food safety research, education and extension projects to help build a modern public health system. Read more about how USDA’s food safety improvements over the past seven years are leading to a safer food supply at www.medium.com/usda-results.

NIFA invests in and advances agricultural research, education and extension and seeks to make transformative discoveries that solve societal challenges.